GROUNDWATER LOWERING FOR A SEWAGE TREATMENT PLANT

Implementation of groundwater lowering for a sewage treatment plant

GROUNDWATER LOWERING FOR A SEWAGE TREATMENT PLANT

Implementation of groundwater lowering for a sewage treatment plant

PICTURE GALLERY

PROJECT DESCRIPTION

There is a sealing wall over a length of 800m. To prevent the water from flowing around the sealing wall, there are 5 well stations along this sealing wall.

Each well station consists of a well chamber containing a deep well pump. This is operated with a frequency converter to enable infinitely variable control. Both the groundwater level and the flow rate of the water are measured by appropriate sensors.

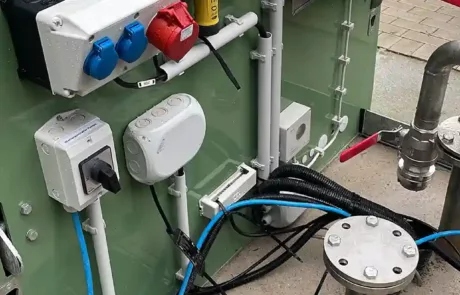

The control unit of each well station is installed in a robust external control cabinet, which is located directly next to the well room.

In addition, there are further groundwater measuring points along the sealing wall that continuously record the height of the groundwater level. A total of 18 groundwater measuring points provide a comprehensive picture of the current situation.

The entire system is realized via a powerful control system in a drive house. This contains a series of control cabinets that supply, control and monitor all well stations and measuring points. The PLC programmed in accordance with the specifications is protected against power failures by a UPS. In addition to the PLC, there is also a VPS to ensure operation of the system in the event of a PLC failure.

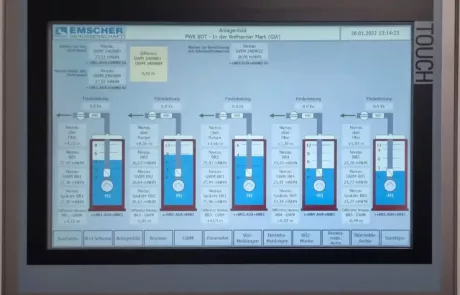

Various display instruments and an HMI show all the measured values that are recorded in the system. In addition, various settings can be made via the HMI, such as the output of the individual pumps if they are in manual mode.

The drive house and the well stations are connected by empty conduits in which approx. 2.7 km of power cables and 7.5 km of control cables run.

PROJECT DESCRIPTION

There is a sealing wall over a length of 800m. To prevent the water from flowing around the sealing wall, there are 5 well stations along this sealing wall.

Each well station consists of a well chamber containing a deep well pump. This is operated with a frequency converter to enable infinitely variable control. Both the groundwater level and the flow rate of the water are measured by appropriate sensors.

The control unit of each well station is installed in a robust external control cabinet, which is located directly next to the well room.

In addition, there are further groundwater measuring points along the sealing wall that continuously record the height of the groundwater level. A total of 18 groundwater measuring points provide a comprehensive picture of the current situation.

The entire system is realized via a powerful control system in a drive house. This contains a series of control cabinets that supply, control and monitor all well stations and measuring points. The PLC programmed in accordance with the specifications is protected against power failures by a UPS. In addition to the PLC, there is also a VPS to ensure operation of the system in the event of a PLC failure.

Various display instruments and an HMI show all the measured values that are recorded in the system. In addition, various settings can be made via the HMI, such as the output of the individual pumps if they are in manual mode.

The drive house and the well stations are connected by empty conduits in which approx. 2.7 km of power cables and 7.5 km of control cables run.

PICTURE GALLERY

DISCIPLINE & ADVANTAGES

Project to permanently lower the groundwater level to prevent contaminated groundwater from flowing into a drinking water area.

Pollution of drinking water has serious consequences. In order to prevent this, constant monitoring of the current measured values by the 18 groundwater measuring points is essential. Efficient pump utilization is also guaranteed. The pumps are switched on or off with frequency control to ensure a long service life and efficient energy use.

DATA & FACTS

Autonomous securing of the water supply for the botanical garden

Energy-efficient use of pumps through frequency control

PERFORMANCE

Project planning and design of the control cabinets

Construction of the 9 control cabinets and installation on site

Expansion of the 5 well rooms

Installation of all probes in the 18 groundwater measuring points

Programming the PLC according to the specifications

Standard-compliant testing and documentation

Commissioning on site

PERFORMANCE

Project planning and design of the control cabinets

Construction of the 9 control cabinets and installation on site

Expansion of the 5 well rooms

Installation of all probes in the 18 groundwater measuring points

Programming the PLC according to the specifications

Standard-compliant testing and documentation

Commissioning on site

DISCIPLINE & ADVANTAGES

Project to permanently lower the groundwater level to prevent contaminated groundwater from flowing into a drinking water area.

Pollution of drinking water has serious consequences. In order to prevent this, constant monitoring of the current measured values by the 18 groundwater measuring points is essential. Efficient pump utilization is also guaranteed. The pumps are switched on or off with frequency control to ensure a long service life and efficient energy use.

DATA & FACTS

Autonomous securing of the water supply for the botanical garden

Energy-efficient use of pumps through frequency control