PUMP CONTROL FOR A COOLING TOWER

Fully automatic control of a cooling tower through pump control

PUMP CONTROL FOR A COOLING TOWER

Fully automatic control of a cooling tower through pump control

PICTURE GALLERY

PROJECT DESCRIPTION

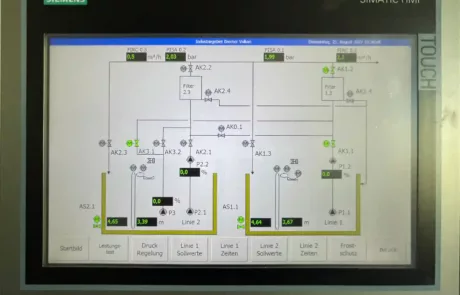

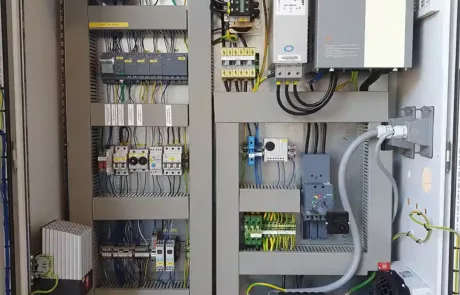

The system is controlled by a series of control cabinets containing five powerful frequency converters and a PLC. The frequency inverters can continuously control the two fans of the cooling towers and three pumps. The temperatures of the incoming and outgoing water as well as the fill level of the collection tank, the data from a contact water meter and a conductivity measurement are recorded. There are also various valves in the system that can be controlled by the PLC. This means that the system can be operated fully automatically.

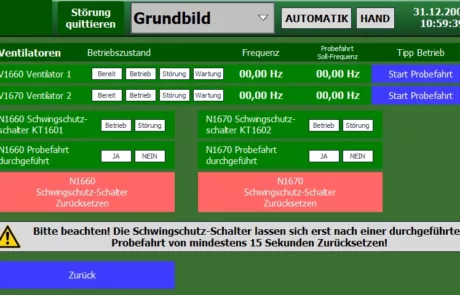

The fans also have vibration protection switches that can automatically detect excessive vibrations.

PROJECT DESCRIPTION

The system is controlled by a series of control cabinets containing five powerful frequency converters and a PLC. The frequency inverters can continuously control the two fans of the cooling towers and three pumps. The temperatures of the incoming and outgoing water as well as the fill level of the collection tank, the data from a contact water meter and a conductivity measurement are recorded. There are also various valves in the system that can be controlled by the PLC. This means that the system can be operated fully automatically.

The fans also have vibration protection switches that can automatically detect excessive vibrations.

PICTURE GALLERY

DISCIPLINE & ADVANTAGES

In a fan cooling tower, the air circulation in the cooling tower is generated by fans. The warm water is directed to the upper part of the cooling tower and sprayed there. The water trickles to the bottom of the cooling tower into a cooling water collection tank and is pumped from there to the consumers.

The system can be operated fully automatically by the PLC control system. The relevant data is automatically recorded and documented in real time so that problems or faults can be responded to immediately. Thanks to the frequency-controlled pumps, the system runs completely energy-efficiently.

DATA & FACTS

Autonomous securing of the water supply for the botanical garden

Energy-efficient use of pumps through frequency control

PERFORMANCE

Project planning and design of the control cabinets

Switch cabinets built and installation on site

Programming the PLC

Standard-compliant testing and documentation

Commissioning on site

PERFORMANCE

Project planning and design of the control cabinets

Switch cabinets built and installation on site

Programming the PLC

Standard-compliant testing and documentation

Commissioning on site

DISCIPLINE & ADVANTAGES

In a fan cooling tower, the air circulation in the cooling tower is generated by fans. The warm water is directed to the upper part of the cooling tower and sprayed there. The water trickles to the bottom of the cooling tower into a cooling water collection tank and is pumped from there to the consumers.

The system can be operated fully automatically by the PLC control system. The relevant data is automatically recorded and documented in real time so that problems or faults can be responded to immediately. Thanks to the frequency-controlled pumps, the system runs completely energy-efficiently.

DATA & FACTS

Autonomous securing of the water supply for the botanical garden

Energy-efficient use of pumps through frequency control