Temperature control is used in various applications, for example in chemical processes, but also for storing temperature-sensitive fillers.

Another important area of application is cooling towers that are operated at a specific temperature interval. The task of temperature control is to keep the temperature constant at a specific setpoint. There are various methods for measuring temperature, the best known being resistance measurement.

Temperature measurement

Temperature measurement is the basis for precise temperature control. In the technical environment, it is always carried out electrically or electronically.

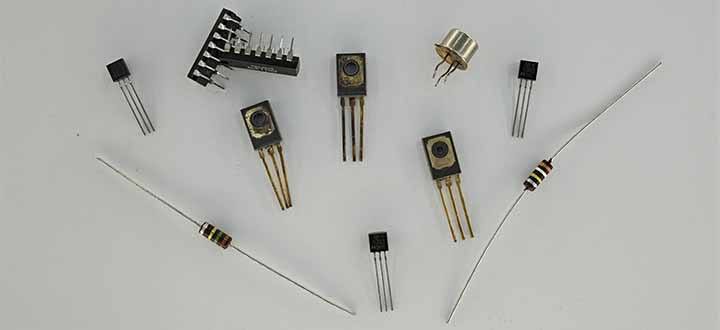

A distinction is made between heat sensors that generate an electrical signal on their own and those that provide a value indirectly. The latter comprise the large group of resistance temperature sensors.

Resistance measurement

The most common method for determining the temperature is to measure temperature-dependent resistances.

NTC thermistors reduce their resistance when the temperature rises.

PTC thermistors increase their resistance when the temperature rises. The so-called platinum measuring resistors (e.g. PT100 or PT1000, the number indicates the nominal resistance at 0 °C) are commonly used for PTC thermistors. These have the advantage of an almost linear resistance curve and are also very temperature-resistant.

There are also measuring resistors made of silicon and ceramic.

Other temperature sensors

With the resistance-dependent temperature sensors, an external voltage must be applied to determine a value. There are also sensors for temperature control that provide a measurable signal on their own. These are usually semiconductor sensors that deliver a current under the influence of heat or across which a voltage drops.

The solid-state circuits should also be mentioned in this context.